Foshan Factory

The CGCH Foshan plant is a branch of Guangdong Zhonghui Green Building Mobile House Technology Co., Ltd., a high-tech manufacturing company specializing in research and development, production, and engineering services for shipping containers, modular buildings, and steel-frame buildings. Through innovative design concepts, advanced manufacturing technologies, and strict quality control, we strive to provide efficient, environmentally friendly, and flexible mobile building solutions to customers worldwide.

Key Advantages

- Large-Scale Production Capacity

Our annual production capacity of sea packaging containers exceeds 60,000 units, and our annual steel structure production capacity reaches 30,000 tons, meeting the diverse needs of customers worldwide.

The company holds three invention patents, more than 30 utility model and appearance patents, and our technical R&D capabilities are industry-leading.

- Diversified Product System

● Modular buildings: sliding units, folding units, prefabricated units, lightweight steel villas, etc., suitable for various use scenarios such as cultural tourism, trade, and industry.

● Innovative product lines: high-end mobile spaces such as space capsules and starry sky homes, helping to modernize residential properties in scenic areas and distinctive commercial districts.

● General contracting engineering services: providing complete solutions from design to production and construction.

- Global Layout

Our products are exported to over 160 countries and regions worldwide, and our services cover emergency rescue, engineering camps, industrial plants, mobile commercial facilities, and other areas.

Application Scenarios

● Cultural and tourism industry: mobile guesthouses, starry sky houses, and tourist reception centers in scenic spots.

● Commercial space: sales offices, temporary stores, mobile kiosks, and restrooms.

● Industry and emergency response: temporary office camps, modular factories, and earthquake relief buildings.

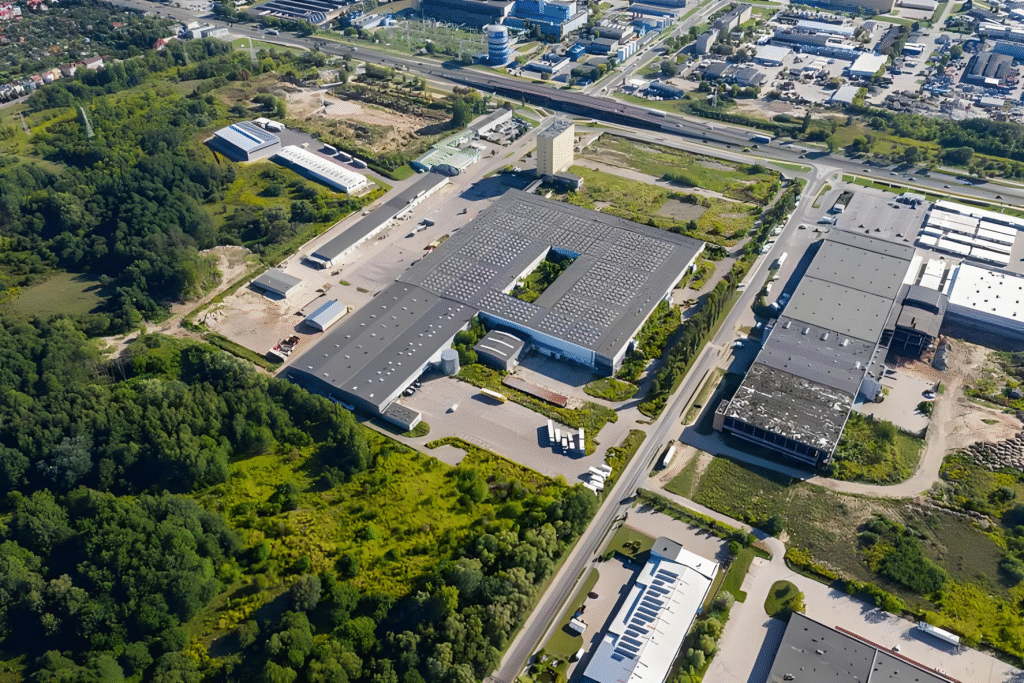

Huainan factory in Anhui

CGCH’s Anhui plant is the group’s key production base in China, specializing in the research, development, design, and production of premium modular buildings and mobile structures. As a leading provider of sustainable building solutions, the plant utilizes cutting-edge technologies, intelligent manufacturing systems, and large-scale production capacity to create high-quality modular structures customizable to customer needs. Its products are widely used in temporary offices, commercial spaces, the hospitality sector, emergency accommodation, and capital construction.

Key Advantages

● Production Scale: Total investment – RMB 1 billion. The first phase covers 200 mu (~133,000 m²), with a total construction area of 120,000 m². Annual production volume exceeds RMB 800 million, creating over 500 jobs. The second phase (380 mu) is planned for further capacity expansion.

● Smart Manufacturing: Includes a single-story steel structure workshop (73,000 m²), a multi-story workshop (13,000 m²), and auxiliary facilities (24,000 m²). Automated production lines and digital control ensure control at all stages – from material processing to module assembly.

● Full-cycle service: From design to installation and service, with both standard and customized solutions available.

● Environmental friendliness: Low-carbon materials, prefabricated technologies, and component reuse meet China’s green standards.

Economic and Social Impact

The project stimulates the local economy, creates jobs, and modernizes the industry. Modular technologies are applied in urbanization, rural development, and other areas, fostering innovation in construction. CGCH’s Anhui plant aims to become a global model in the modular construction industry.

Jiangmen workshop

The CGCH Jiangmen factory is the main production base of Guangdong Zhonghui Green Building Mobile House Technology Co., Ltd. It is located in Liansu Industrial Park, Heshan Industrial Town, Heshan City, Guangdong Province, and covers an area of approximately 72,000 square meters. The company has two modern factory buildings with a total construction area of over 54,000 square meters, which are used for the efficient production of marine packaging boxes and steel structures. As a leading modular building manufacturer in China, we emphasize intelligent manufacturing, high quality, and global service as our core competitive advantages and strive to provide comprehensive, top-notch mobile building solutions to customers worldwide.

Key Advantages

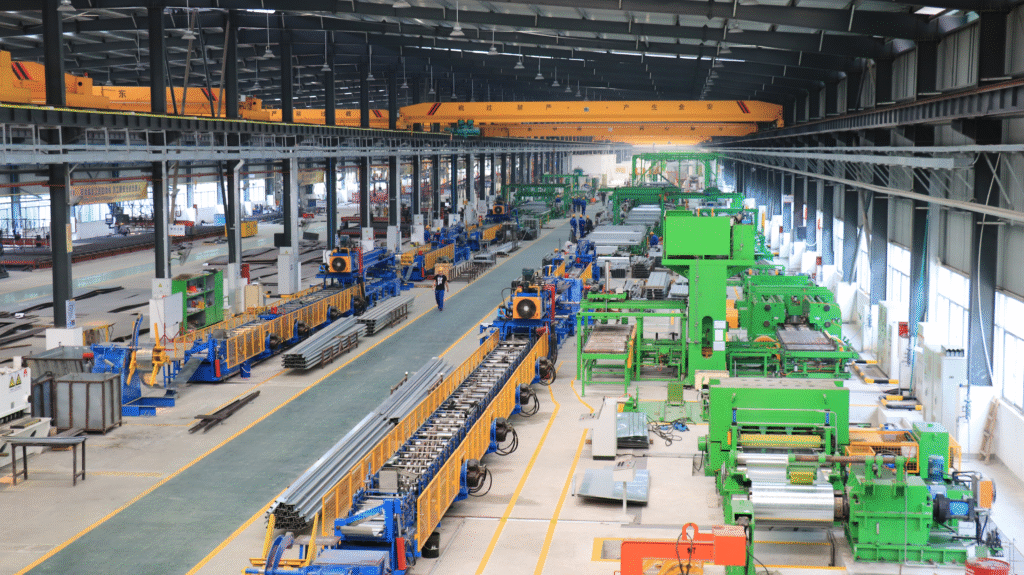

- Industry-Leading Fully Automated Seaworthy Packaging Box Production Line

● The industry’s only fully automated seamless production line, with a total investment of approximately RMB 70 million, implements automated production processes such as lifting, turning, and conveying, significantly improving efficiency and precision.

● Daily production capacity reaches 150 units, and annual production capacity exceeds 60,000 units, meeting the large-scale demand of the global market.

● Two professional testing laboratories conduct rigorous tests for waterproofness, penetration, roof load, stacking, and lateral pressure, ensuring the high quality and durability of products.

- Efficient and Intelligent Steel Structure Production Line

Total equipment investment exceeds RMB 20 million. It uses a two-line parallel production mode and is equipped with industry-leading equipment, including:

● CNC flame cutting machine, 2000-type assembly machine, gantry submerged arc welding machine.

● 60B/40A calibrating machine, 50MM CNC drilling machine, 14-head shot blasting machine.

● Monthly production capacity is 3,000 tons, and annual production capacity is 30,000 tons. The production process is fully mechanized, ensuring high efficiency and precision.

● The environmentally friendly water-based paint application process complies with green manufacturing standards and considers both quality and sustainability.

Product Applications

● Business and cultural tourism: mobile kiosks, starry sky houses, light steel villas, reception centers in scenic spots.

● Industry and infrastructure: engineering camps, modular factories, temporary office space.

● Emergency and livelihoods: earthquake relief housing, mobile medical units, emergency relocation housing.

Mission and Vision

Guided by the core concept of “intelligent manufacturing, quality first,” CGCH Jiangmen continues to advance innovation in modular building technologies and strives to become a model production base in the global mobile building industry, providing customers with efficient, reliable, and environmentally friendly construction solutions.

Saudi Arabia factory

Introduction

Located in the vibrant city of Riyadh, Container Home Factory is a pioneering company specializing in the production of container homes. These homes are not typical dwellings; they are eco-friendly, cost-effective, and designed with the future in mind. The factory’s mission is to provide sustainable housing solutions that meet the growing needs of the population while minimizing environmental impact.

Community Impact

The Container Home Factory is more than just a business; it’s a community initiative. By providing affordable housing solutions, the factory helps alleviate the housing crisis in Saudi Arabia. The homes are accessible to people of all income levels, making homeownership a reality for many.

Future Plans

Looking ahead, Container House Factory has ambitious expansion plans. As demand for sustainable housing grows, the factory aims to increase production and reach more communities in need. They are also exploring new technologies and materials to further enhance the quality and sustainability of their homes.

Conclusion

The Container House Factory in Saudi Arabia is a beacon of innovation in the housing industry. It represents a shift toward sustainable living and a commitment to providing quality homes for all. As we continue to face the challenges of urbanization and climate change, the Container House Factory serves as a model for the future of housing.

More information about the Container House Factory and its innovative housing solutions can be found on their website: https://www.cgchcontainer.com/

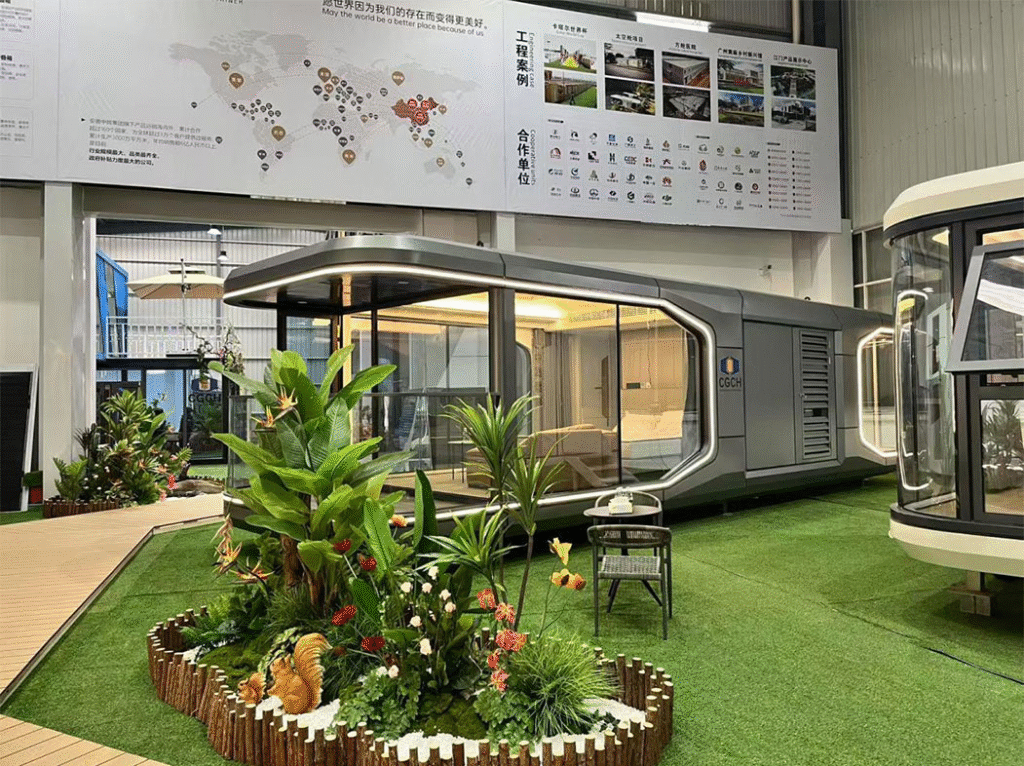

Suzhou Factory

The CGCH Suzhou Exhibition Hall is a modular exhibition center built by Guangdong Zhonghui Green Building Mobile House Technology Co., Ltd. (CGCH) in eastern China. It specializes in showcasing the company’s innovative products and solutions, including shipping containers, modular homes, and steel-frame buildings. A window into cutting-edge mobile building technologies, the exhibition hall focuses on immersive experiences, scenario-based displays, and intelligent interaction, allowing visitors to intuitively experience the efficiency, flexibility, and sustainability of modular buildings.

Showroom Highlights

- Full Product Display

● Modular Commercial Spaces: Quickly Assemble Boxes, Folding Boxes, Space Capsules, Mobile Shops, etc., suitable for cultural tourism, retail, and temporary businesses.

● Luxury Residential Solutions: Lightweight Steel Villas, Starry Sky Homes, and Residential Container Homes, showcasing comfort and design aesthetics.

● Industrial and Emergency Buildings: Residential spaces for engineering camps and earthquake-resistant buildings, embodying rapid deployment and durability.

- Intelligent Interactive Experience

● Digital Sandbox: A dynamic demonstration of the entire modular building process, from production to assembly.

● Virtual Construction in VR: An immersive experience of spatial effects in various scenarios.

● Environmental Technology Demonstration: An analysis of green building technologies, such as water-based paint technology and energy-efficient building materials.

- Connect to a comprehensive service

● Professional consulting team: Provides comprehensive consulting services, including product customization, engineering design contracting (EPC), leasing, etc.

● Global case study wall: Showcases real-life scenes of CGCH projects in over 160 countries and regions.

Wuhu Factory

Wuhu Factory – A Global Intelligent Manufacturing Center for Modular Construction

CGCH’s Wuhu Factory is a key manufacturing facility within the CGCH Group, specializing in the development and production of high-tech modular buildings and mobile structures. Focused on intelligence, scalability, and sustainability, the factory is a modern production center integrating R&D, production, and testing. Its products are widely used in commercial spaces, tourism, emergency construction, permanent housing, and specialty areas, offering global customers comprehensive construction solutions.

Key Advantages

- Intelligent Manufacturing System

● Total Investment: Approximately RMB 100 million in equipment, including seven main production lines:

✅ Quick-Assembly Container Line | ✅ Expandable Container Line | ✅ Sea Packaging Container Line

✅ Light Steel House Line | ✅ Space Capsule Line | ✅ Fixed Container Line | ✅ Z-shaped Container Line

● Full production cycle:

From raw material processing to finished product assembly. Daily capacity: 1,500-1,800 units, monthly production of lightweight steel structures: over 300,000 tons.

● Modern equipment:

2 automatic powder coating lines | 1 varnishing line

2 composite panel lines | 2 “gold panel” production lines

Fully mechanized transportation, use of environmentally friendly water-based paints, compliance with international standards.

- Strict quality control system

● 2 specialized testing systems for 5 key tests:

Waterproofing | Penetration | Roof load

Stacking | Lateral pressure

Ensures product safety and durability under extreme conditions.

- Eco-friendly production and high efficiency

● Optimized layout ensures a smooth process and industry-leading productivity.

● Modular design reduces construction waste, with a material recycling rate exceeding 90%, meeting carbon neutrality goals.

Production Capacity and Social Relevance

● Annual Production Value: Over RMB 1.5 billion at full capacity, creating over 800 jobs.

● Technological Contribution: Promoting the development of prefabricated construction in the Yangtze River region, participating in Belt and Road projects.

● Key Projects: Products are used in international hotels, energy camps, medical modules, and other premium segments.

Future Plans

The Wuhu plant will continue to implement AI quality control, robotic welding, and other innovations, striving to become a “beacon factory” in the global modular construction industry and redefining the standards for fast, green, and smart construction of the future.